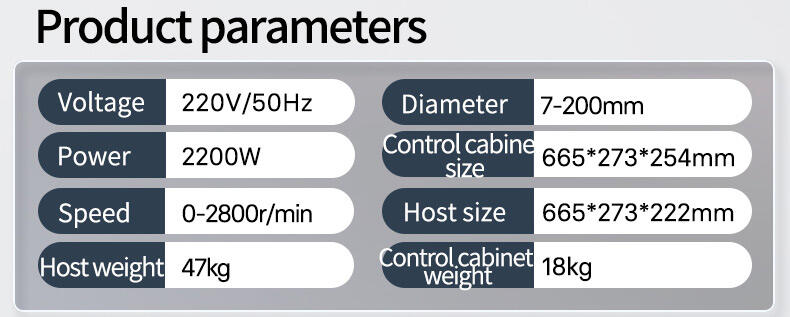

| Specification | Details |

| Model | T-3300 |

| Application | Boiler Pipeline Dredger |

| Power Supply | 220V/50Hz |

| Motor Power | 2200W |

| Rotation Speed | 0-2800r/min (adjustable) |

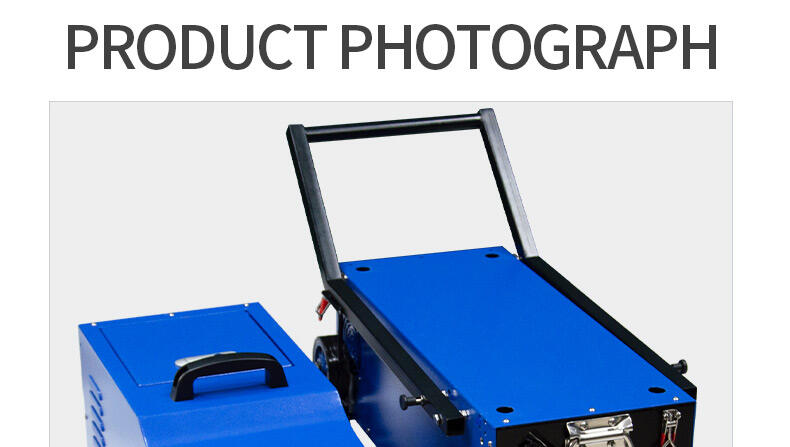

| Weight | 18KG (machine only), 47KG (total) |

| Dimensions (Main Body) | 665mm x 273mm x 254mm |

| Dimensions (Accessory) | 665mm x 273mm x 222mm |

| Pipe Diameter Range | 7mm to 200mm |

| Performance | Powerful and fast |

Description:

Motor Upgrade:Equipped with a powerful 2200W motor for enhanced performance.

Rotation Speed: Upgraded to a variable speed ranging from 0 to 2800 R/MIN, ensuring fast and efficient dredging.

The T-3300 boiler pipeline dredger has been upgraded with a 2200W motor and an increased rotation speed of 0-2800 RPM. This upgrade enhances the dredging speed and provides stronger penetrating power, effectively addressing hardened and compact deposits inside pipelines. The modular design allows the machine to be used for operations within manholes. It is suitable for curved water-cooled wall tubes, boiler water-cooled wall tubes, S-shaped bends in boiler water-cooled wall tubes, large-diameter shell tubes in heat exchangers, and boiler pipelines

Industrial tube cleaning machine(KT-3300)

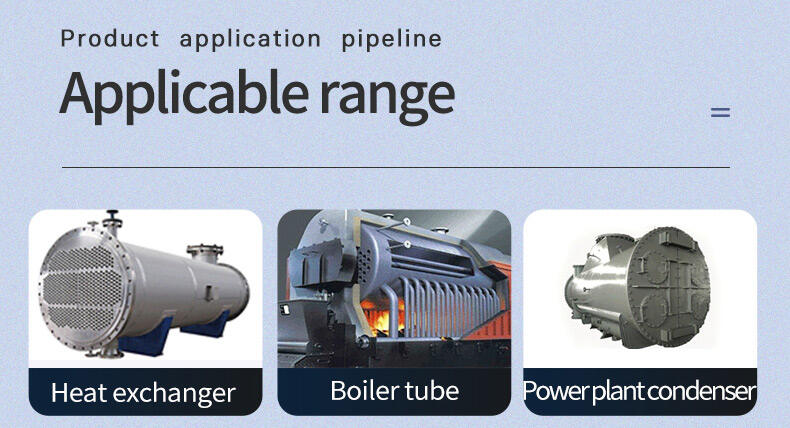

Suitable for boilers,Air preheater,evaporator,Heat exchanger,condenser etc;No damage to the pipe wall;

function:air/water flusing;Through bend tube;

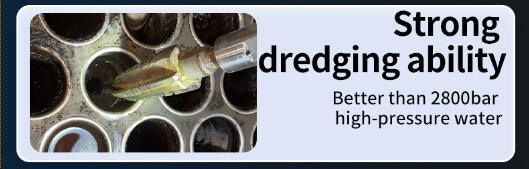

Strong dreging ability :better than 2800 bar high-pressure water

220W high power:the high-power moter drives the drill bit or brush to rotate and clean the dirt in the tube

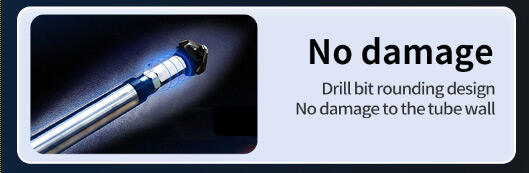

No damage:Drill bit rounding design ,no damage to the tube wall

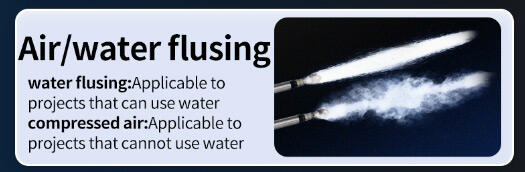

Air/water flusing:use water:Applicable to projects that can use water;compressed air:Applicable to projects that cannot use water

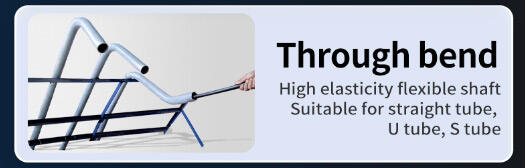

Through bend tube:Suitable for straight tube, U tube, S tube

0-2800r/min Stepless speed:Adjustable speed

Combined design:Combined design, the control cabinet can be passed through the manhole;Single person operation

Applicable range:Heat exchanger;Boiler tube;Power plant condenser ;Air preheater;Gas primary cooler ;evaporator ;condenser

Professional cleaning machine, one machine with multiple uses;Suitable for cleaning various types of blocked pipelines

Product parameters:Voltage ;diameter ;power ;Control cabinet size ;speed ;Host size ;Host weight;Control cabinet weight

Standard accessories:flexible shaft;Water pipe

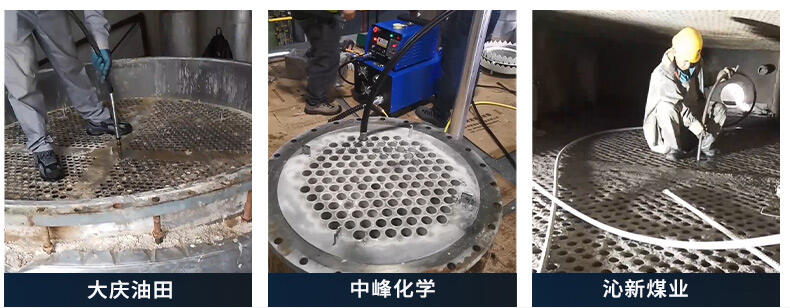

Founded in 2009, Anhui Kuaitong is specialized in designing, producing and sales of air duct cleaning machines, kitchen exhaust cleaning machines, tube cleaner machines, boiler tube cleaners, heat exchanger tube cleaners, accessories and other industrial pipe cleaning machines over a decade and keeping up to meet customer demands all the time.

Our customer includes and not limited to building and device maintenance companies, heating system, ventilation system, central air conditioning, chemical industry, petrochemical industry, power plant, manufacturing company, food processing industry, transportation and distribution system, paper industry, ship industry, maritime industry etc.

Anhui Kuaitong is committed to the development of domestic and foreign markets, products are exported to 58 countries and regions in the world. The products are CE certified and gained the consistent recognition and praise by our customers.

15 years of high-tech enterprises in China:ISO9001 certification and EU CE certification

Q: Are you trading company or manufacturer?

A: We are professional manufacturer, all of our machines are designed and produced in our own workshop. And we trade our products with our clients directly.

Q: Can you do OEM ?

A: Yes, OEM is acceptable.

Q: How many different types of products your company manufactures?

A: Now we mainly produce kinds of air duct cleaning machines, kitchen exhaust cleaning machines, tube cleaners etc.

Q: When can I get the price?

A: Usually we quote within 8 hours after we get your inquiry.

Q: What’s your MOQ?

A: We don’t have MOQ, since we are factory and most of machines are available in stock.

Q: How long is your delivery time?

A: The general delivery time is 3-15 days after receiving your order confirmation. Another, if we have the goods in stock, it will only take 1-2 days.

Q: What is your term of payment?

A: TT, credit card, western union, Paypal etc.

Q: Which certificate do you have?

A: CE.

Q: What’s your term of the delivery?

A: We provide EXW, CFR, CIF, DDP, DDU etc.

Q: Which shipping way can you provide?

A: We can provide shipping by sea, by air and by express.

Q: What’s your after-sale service?

A: Our quality warranty period is one year.

Our friendly team would love to hear from you!